Solution

fter.io software

Features for Managing the Lifecycle of your Installed Base

Installed base in logical structure

– Freely configurable asset registers

– Generate templates for all asset types

– Create structure that is logical for your existing processes and needs

State of the art data collection

– Generate service views for troubleshooting

– Use data analytics toolkit to create alarms and work orders

– EdgeAPP to read/write/manipulate data in local network

– CloudAPP to control EdgeAPPs and enable visualizations & data analytics

Enhanced work order processing

– Unlimited number of work order templates

– Unrestricted design of status flows

– Personalized views with relevant data only

Customized invoicing material generation

– Add resources to your work orders

– Create invoicing material

Predictive

maintenance engine

Unplanned downtime always leads to high costs. fter’s predictive maintenance engine collects sensor data, identifies patterns using AI algorithms, and predicts the optimal maintenance time for your machines.

- Up to 40% less downtime thanks to early fault detection

- Reduce maintenance costs by 15–25% because service is performed only when truly needed

- Data-driven decision support increases asset availability and extends the lifespan of critical components

Asset Management

Ticket System

Workflow Designer

Documents

Open Interfaces

IoT Edge

Self-service

knowledge hub

Obtaining information is often time-consuming for both machine builders and operators. Service technicians and operators lose time because they have to search through manuals and tickets to find the relevant documentation or corrective actions.

A central portal consolidates manuals, videos, best-practice articles, and community knowledge — supplemented by semantic search and chatbot assistance. The whole lifecycle of a machine or plant is also documented there.

- 30% shorter problem-solving times thanks to immediate access to relevant know-how

- Relief for the service desk: Up to 40% fewer support tickets

- Scalable expert knowledge: New knowledge is automatically made available to all locations

Connectors for all leading automation platforms

Advanced condition monitoring with live dashboard

It is often very time-consuming for machine builders and operators to create an up-to-date overview of a distributed installed base.

As a result, responding to failures remains a local task — without deriving generally valid and reusable conclusions.

fter software collects machine data, securely transfers it to the cloud, and displays data and time series in a live dashboard. The system also generates configurable warnings and alarms.

- OEE dashboard: fter enables you to increase understanding of the status of your assets in real time. Critical KPIs are always available on desktop and mobile devices

- Auto-ticketing: Automated alerts help you to reduce the alarm-to-action gap, enabling service personnel to be activated or spare parts to be reserved early

- Connectors to enterprise software: Using open interfaces, fter connects to your existing SCADA, ERP, or MES solutions. This is relevant for inventory planning or invoice generation

Automated OTA updates

Asset owners often have to install firmware and software updates manually — a logistical nightmare that also creates significant security gaps.

fter plans over-the-air updates (OTA) centrally, rolls them out in stages, and tracks them, while the system automatically supports reverting to previous versions.

- Up to 70% less on-site effort thanks to remote update rollouts

- Higher security compliance: Security measures reach all devices in the shortest possible time

- Verifiable update history: Transparency over all version levels, from firmware to applications

Rental models & pay-per-use billing

High investment costs discourage manufacturing companies from modernizing their equipment, even though it would be economically sensible.

With flexible OPEX models, customers pay a monthly rental fee or a usage-based charge. fter software handles billing automatically.

- Lower investment barriers: CAPEX becomes predictable OPEX

- Win-win partnership: The machine builder benefits from continuous revenue, while the customer only pays when the machine creates value

- Data-driven optimization: Usage data enables new services (feature expansions and improvements) and ensures long-term customer engagement

Dynamic deployment planner

Often, organizations still coordinate service and maintenance tasks manually. This leads to empty trips, overtime, and potentially missed service agreements (SLAs), as unexpected failures disrupt the schedule.

An AI-powered deployment planner consolidates data from enterprise software, simulates possible scenarios in seconds, and continuously adjusts shift, route, and personnel assignments.

- Up to 25% less travel and setup time thanks to optimized routes and rolling planning

- SLA compliance > 98%, as emergencies are automatically integrated into the schedule without jeopardizing other tasks

- Motivated technicians through transparent shift logic and fair workload distribution via algorithm

Automated prioritization of work orders

Teams often handle maintenance and repair tickets according to the “loudest voice first” principle. As a result, critical equipment does not always receive immediate attention, leading to increased consequential damage and costs.

The system automatically weights all incoming orders based on risk, equipment criticality, production windows, spare part availability, and legal deadlines, and assigns them A, B, or C priorities accordingly.

- 40% faster resolution of issues for A-assets; prevents production downtime

- Audit-proof decision logic: Every priority is transparently documented; reduces internal debates

- Optimal resource utilization: Teams focus first on tasks with the highest value contribution, not on “loud” tickets

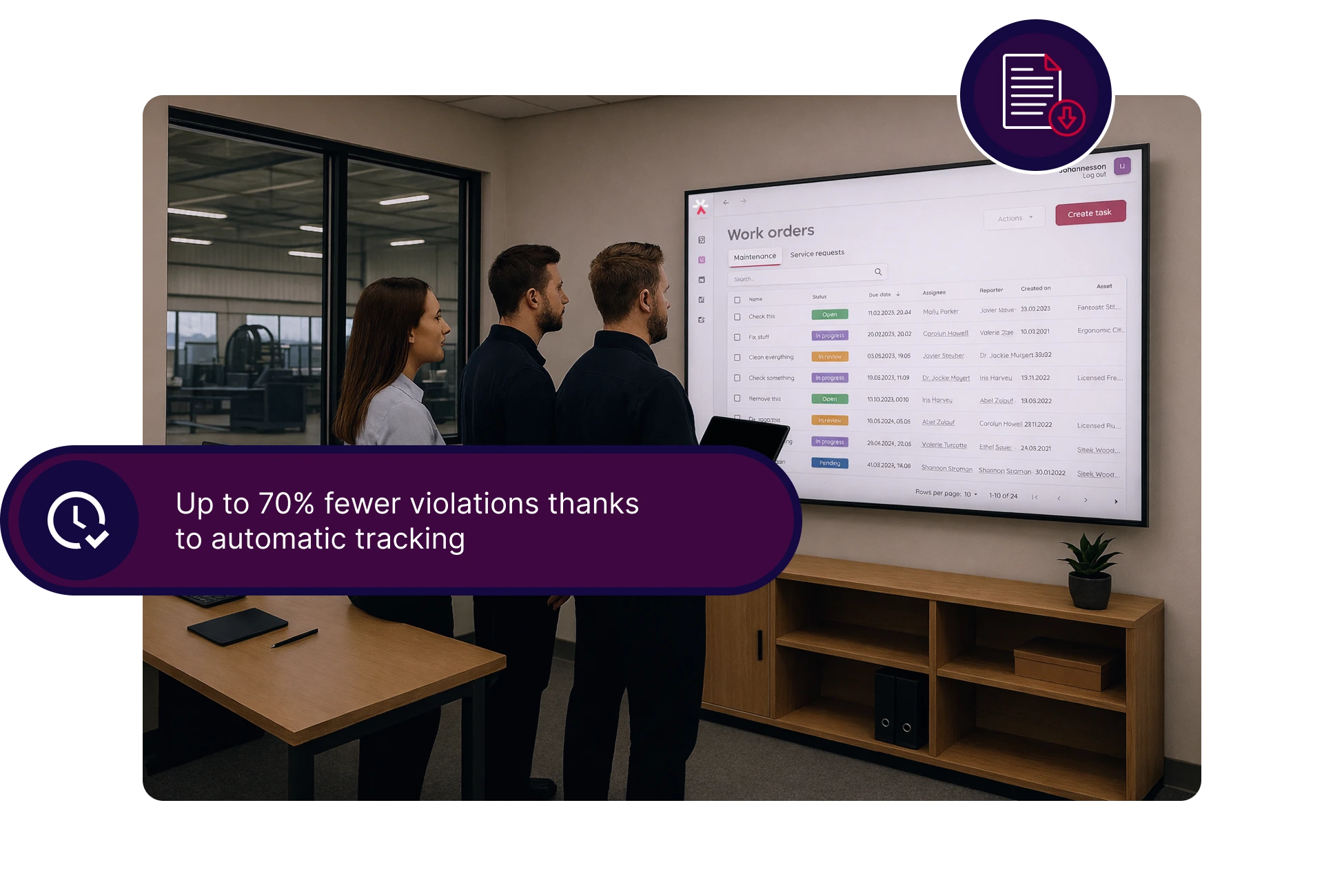

CRA compliance & security tracker

Under the Cyber Resilience Act (CRA), manufacturers and operators must ensure secure development, documentation, vulnerability handling, and lifecycle management of connected products. Missing SBOMs, lacking update procedures, or insufficient security monitoring can block market access or trigger product recalls. Manual spreadsheets and fragmented tools make compliance nearly impossible.

The tracker automatically manages SBOMs, software and firmware versioning, PLC program back-ups, restore workflows, and update handling for all OT devices. It continuously scans for vulnerabilities, maps them to CRA requirements, and ensures remediation workflows are executed and documented.

- CRA audit readiness in hours instead of days – all technical documentation, SBOMs, and update logs available at the push of a button.

- Up to 70% fewer compliance gaps because vulnerabilities, missing back-ups, or outdated PLC code are automatically detected and escalated.

- A central “single source of truth” ensures full lifecycle documentation and removes the need for manual filing or scattered tooling.