Use case – Spare part sales

CRA 2027 for Industrial Manufacturers

Benefits of strengthening digital security

Key requirements of the Cyber Resilience Act for businesses

fter rebranded as flexAM in the DACH region

CRA compliance: What the EU Cyber Resilience Act requires by 2027

Use case

OEM: Spare part sales

Use case:

Optimizing spare part sales for aftermarket success

Spare part sales are a cornerstone of the aftermarket business for industrial machine builders. These sales ensure that customers can maintain and repair their machinery efficiently, minimizing disruptions and extending the lifecycle of their equipment.

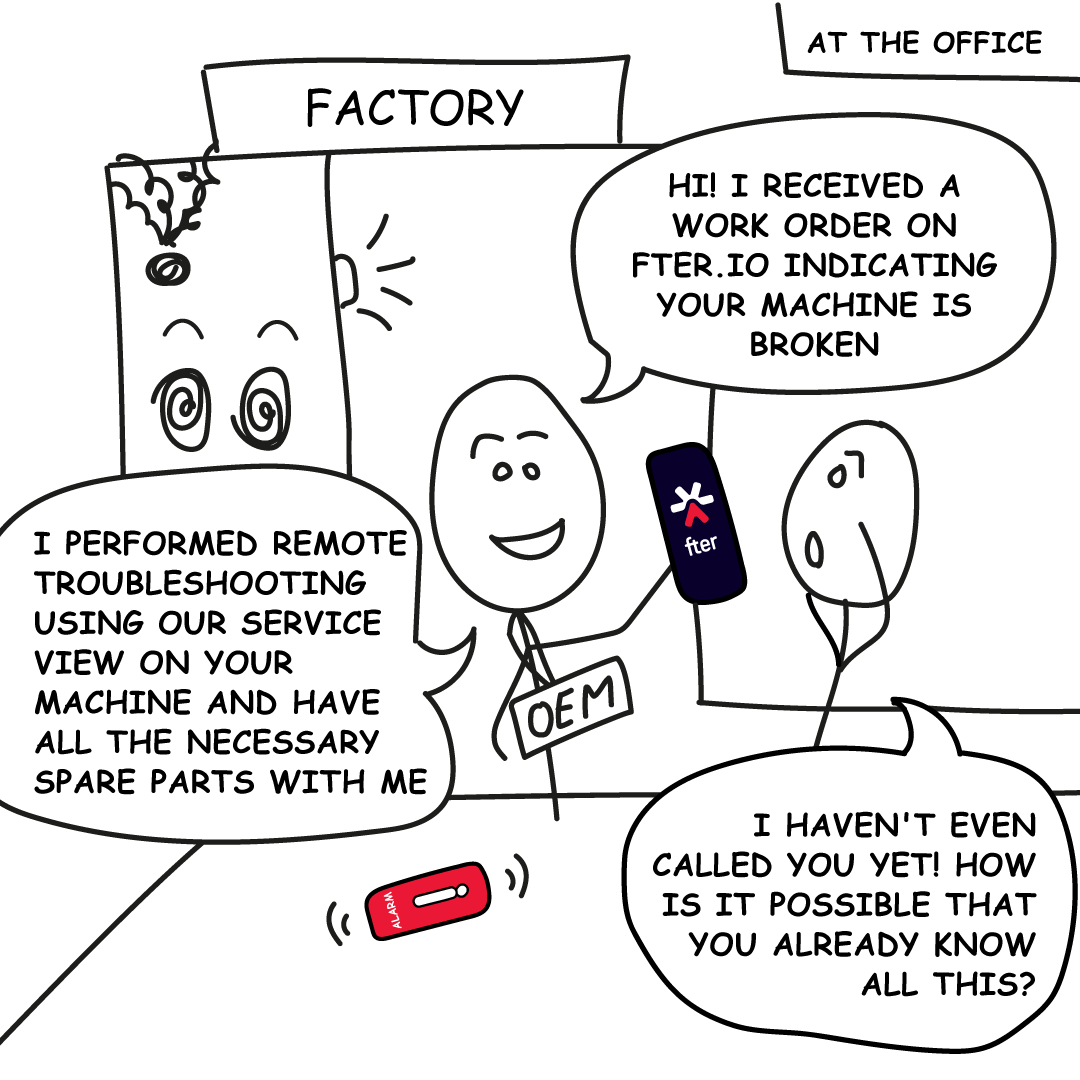

To excel in spare part sales, OEMs need detailed knowledge of their installed base. Platforms like fter.io provide this insight by allowing OEMs to track the status of components, identify end-of-life parts, and recommend suitable replacements. This level of detail ensures that customers receive the right parts at the right time, reducing delays and enhancing satisfaction.

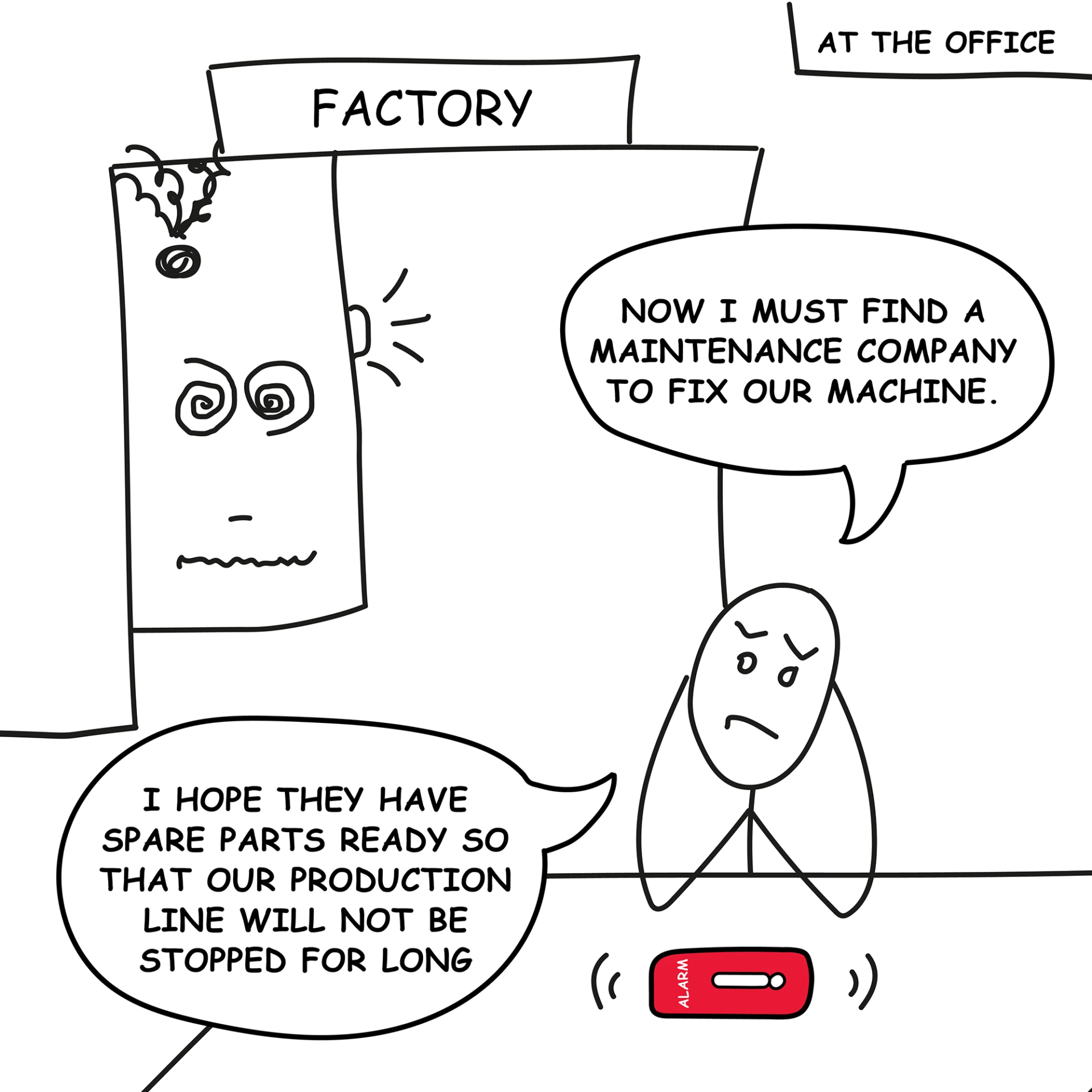

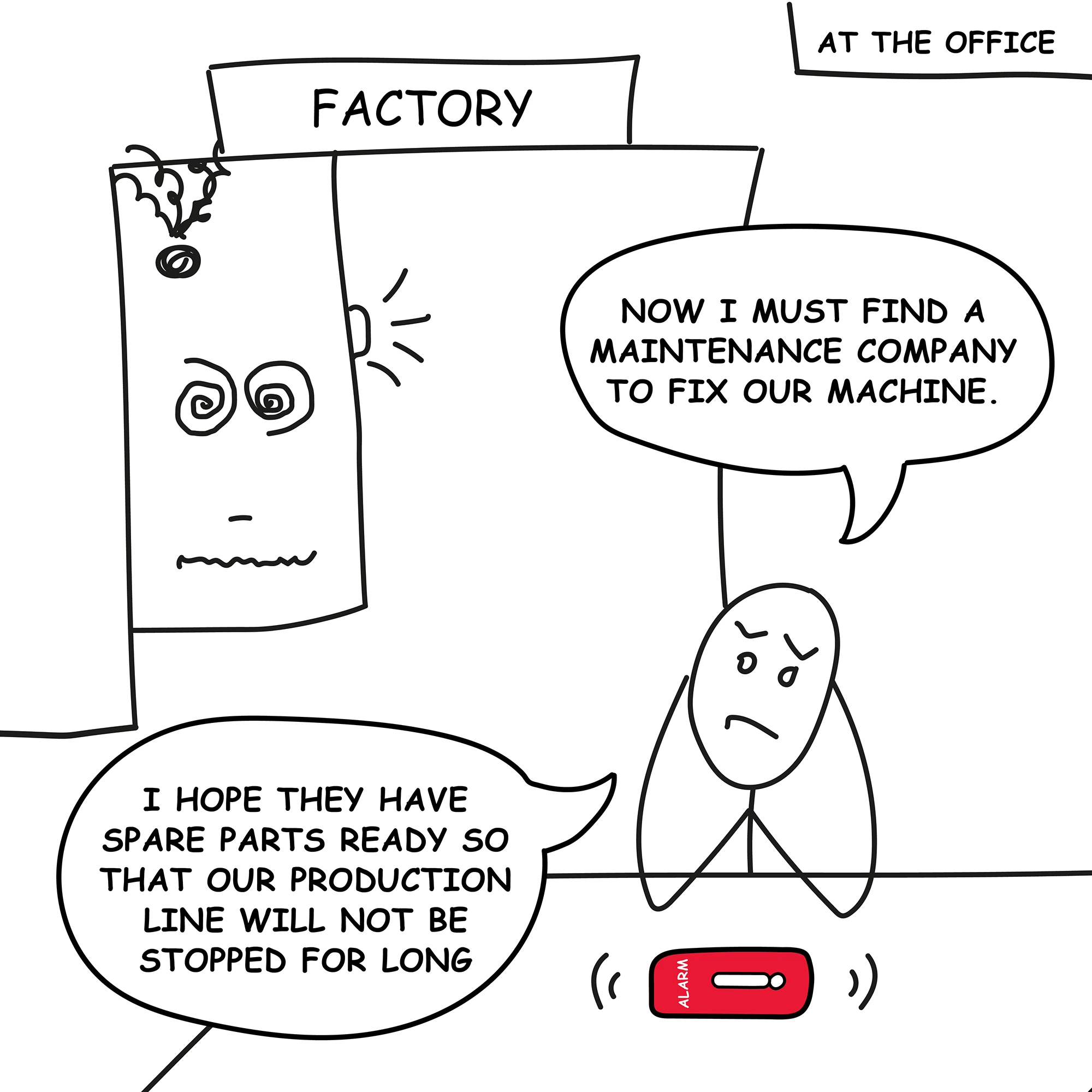

Connectivity adds another layer of value by enabling real-time monitoring of machine performance. This capability allows OEMs to predict when parts will need replacement and offer proactive solutions. Additionally, fter.io’s ability to automate work orders and streamline the invoicing process ensures that spare part sales are both efficient and profitable.

By focusing on spare part sales as part of a comprehensive aftermarket strategy, OEMs can create a reliable revenue stream while supporting their customers’ operational needs. This approach not only drives profitability but also strengthens the OEM’s reputation as a trusted partner in the industrial sector.

Value proposition: Boosting spare part sales

Empowering OEMs to maximize spare part revenue

Overall, fter.io provides a comprehensive solution that not only enhances the efficiency and profitability of managing the installed base but also enables new business opportunities and operational models. By integrating advanced connectivity and digital capabilities, fter.io helps industrial machine builders unlock the full potential of their aftermarket, leading to sustained growth and increased long-term value.